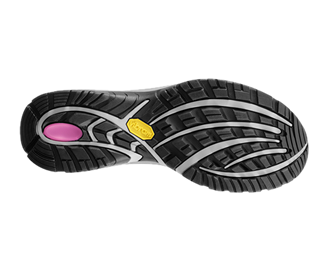

Sole

A whole variety of different underfoot situations have to be considered when designing a sole unit. SCARPA® has worked exclusively with the world's leading sole manufacturers (Vibram® and Skywalk®) to develop soles that will meet these different requirements and performance

characteristics.

Our Soles

A whole variety of different underfoot situations have to be considered when designing a sole unit. SCARPA® has worked exclusively with the world's leading sole manufacturers (Vibram® and Skywalk®) to develop soles that will meet these different requirements and performance characteristics.

We recommend that you follow these guidelines to get the most out of your boots.

- After each use rinse off mud and dirt with clean water. Remove any stubborn dirt with a sponge, damp cloth or brush. If your boots are particularly dirty you can use a cleaning product such as Nikwax Footwear Cleaning Gel.

- Dry your boots naturally over time in a cool, dry place with good air circulation (Never force dry your boots using heat, as this will damage the leather uppers)

- Regularly treat them with a suitable waterproofing treatment applicable to the type of boots you have (See below). We would recommend re-proofing the boots whenever they get particularly dirty or when water stops beading (turning to droplets) on the surface of the boots.

- Take care to apply treatments to tongues, D. rings and hooks. Do not over treat them as this can soften the leather and damage stitching.

Terra

A high quality 2mm leather ideal for the entry level boots in our range. Montana leather is very supple and very lightweight which gives a soft, comfortable fit ideal for entry level boots. The leather is oiled to boost natural water resistance and to improve the cosmetic finish. Use a proofing agent from new, for best results we recommend SCARPA HS12 cream or a water based wax treatment such as Aqueous Nikwax.

It is a common misconception that boots with a Gore-Tex membrane require less care, this is not the case. Leaving a Gore-Tex boot untreated will likely damage the boot. Gore-Tex boots should be cleaned and re-proofed regularly in accordance with the care instructions for the specific materials below.

Over time particles of dirt and debris will build up on the inside of your boots, this can cause abrasion which can damage the Gore-Tex lining of your boots which can cause the boots to leak. In order to extend the life of your footwear it is best to periodically remove the insole and rinse the inside of the boot with clean warm water. Always leave your boots to dry naturally following this process.

Ranger 2 Activ / Delta Activ

High quality leather of 2.4 or 2.6mm in thickness, they are ideal for fell or lightweight hillwalking boots. Calf leather undergoes a traditional tanning process which helps to make it durable and highly water resistant. Use a proofing agent from new, for best results we recommend SCARPA HS12 cream or a water based wax treatment such as Aqueous Nikwax.

SL Activ

A 2.7-2.9 mm leather. The extra thickness and durability of this leather is perfectly suited to stronger hill and mountain walking boots, where extra support and resistance to scuffing is required. Sherpa leather undergoes a full HS12 silicone tanning treatment which, coupled with the extra thickness of the leather, boosts water resistance and stops the leather from wetting out too easily. We recommend the use of SCARPA HS12 cream or Aqueous Nikwax from new.

Kinesis Tech / Mythos Tech

Nubuck is a full grain leather where the outer surface of the leather has a finely sanded, texturised finish, which gives the boot an added appeal. All SCARPA Nubuck leathers are HS12 treated and will give the same performance as Sherpa leather, although the surface finish will change over time. Use specialist Nubuck treatments such as Nikwax Nubuck and Suede from new to keep the uppers in the best condition. SCARPA HS12 can be applied however this will flatten the texturised finish of Nubuck leather and darken the colour. The original finish can be restored using a suede brush.

Manta / Mont Blanc

These are premier leathers used on full mountain boots where maximum strength, support and abrasion resistance is required. These leathers are used with the tanned finish reversed with the textured side out and the tanned surface inside. This helps to protect the tanned surface of the leather and the extra surface area of the brushed finish helps to boost water resistance. All SCARPA reversed leathers are HS12 treated. For reversed leather we recommend Nikwax Nubuck and Suede treatment, followed by a light brushing with a suede brush, this will retain the appearance of the reversed leather.

Cyclone / Mustang / Baltoro / Kinesis

Suede does not offer the same level of water resistance as smooth leather however suede is both lightweight and relatively durable which makes it the ideal choice for lightweight trekking models. Suede is thinner and more supple than full grain smooth leather but still requires regular care. Take care to re-proof areas where suede joins other materials to ensure that the suede retains maximum flexibility. We recommend use of Nikwax Nubuck and Suede or Graingers G-Max from new.

Rebel / Rebel Ultra / Rebel Carbon

A fabric studied especially for SCARPA. KCN-TECH is derived from three high-tenacity textile fibres woven together, by Schoeller, to form an incredibly lightweight, durable waterproof breathable fabric. Ideal for use on our Mountain Elite line KCN-Tech ensures the perfect balance between performance and weight. S-Tech is a completely synthetic alternative to leather which provides durability and water resistance with a radical weight saving in comparison to leather. Another benefit of S-Tech is that it has a great memory which means that once is it ‘lasted’ into a shape it will hold that shape as the boot ages despite abrasion etc. This makes it perfect for use on our Mountain Elite line. We recommend using Nikwax Fabric and Leather proof or Grangers G-Max periodically to ensure the highest level of water resistance is maintained.

Phantom Series / Charmoz Pro / Rebel Lite

A synthetic material, made by Schoeller, which ensures maximum durability with minimum weight. Combined with S-Tech this allows us to achieve a lightweight boot which is strong enough for summer and winter mountaineering, scrambling and Via Ferrata. We recommend using Nikwax Fabric and Leather or Grangers G-Max periodically to ensure that the highest level of water resistance is maintained

Last

SCARPA develop a last to specifically suit the end use of each boot. As a result, when you step into a SCARPA boot, you can be sure it has been carefully designed to suit you and your activity. Additionally, SCARPA were the first company to develop a purpose made last for women's boots. Today every ladies specific model has a dedicated female last. These lasts are slimmer in the mid foot and heel areas (Note: This female last may also be appropriate for a slim, low volume male foot and conversely a high volume, broad female foot may be better suited to the standard last).

Explode the myths!!